By A&D Business Unit Director Jim Will

SkyWater Technology, the leading U.S. foundry for radiation-hardened process technologies, is set to showcase its latest advancements in 90 nm FDSOI CMOS technology at the upcoming GOMACTech conference, taking place in San Diego from March 20-23, 2023.

In advance of the show, we sat down with SkyWater A&D Business Unit Director Jim Will to ask a few questions and learn how this developing platform enables a range of extreme environment applications. We invite you to read our quick Q&A below and bring your own questions to GOMACTech where members of our Aerospace and Defense team will be eager to talk with you about your project.

What type of rad-hard technologies does SkyWater design and fabricate?

SkyWater streamlines the path to commercialization for a variety of devices along the radiation-hardened spectrum from strategic rad-hard to radiation tolerant.

- Strategic rad-hard components are designed using specialized materials and manufacturing processes that provide the highest levels of radiation hardness, ensuring that they can operate reliably in extreme conditions. These applications or systems are typically critical to national security, defense or space exploration.

- Rad-hard components are also designed to withstand radiation, but they are not necessarily optimized for the most extreme environments. These components are still highly resistant to radiation-induced failure and are suitable for use in many defense and space applications.

- Radiation tolerant components are designed to operate without failure in environments where the radiation levels are relatively low.

Why is important to develop strategic rad-hard manufacturing capability in the United States?

Developing a strategic rad-hard capability is essential for the United States to uphold national security. Strategic rad-hard technology enables critical defense applications and infrastructure to withstand harsh radiation environments without failures or malfunctions — ensuring the safety and reliability of those systems. By having domestic strategic rad-hard capabilities, the U.S. reduces its dependence on foreign sources for critical components and ensures the security of its supply chain.

Why is SkyWater an ideal manufacturing partner for strategic rad-hard technology?

As a stateside commercial foundry, we put security first. SkyWater is ITAR-certified and a Category 1A Trusted manufacturer, which makes us an ideal partner for anyone who prioritizes security in their design projects.

In addition to security, we emphasize quality. Quality is essential in the precise work that SkyWater does — in the accuracy of our products and services — as well as its execution through certified processes. Read more about our commitment to quality and our certifications.

Why is ITAR certification important?

ITAR stands for International Traffic in Arms Regulations, which is a set of regulations that control the export and import of defense-related articles and services on the United States Munitions List, or USML. To be ITAR certified means that a company has been authorized by the U.S. Department of State to handle defense articles or services covered by ITAR.

Being ITAR certified allows a company to work on defense contracts and handle sensitive information or technologies that are covered by ITAR regulations. It also demonstrates a commitment to maintaining the highest levels of security and compliance with government regulations, which can be an important factor for customers who require trusted and secure partners for their critical defense projects.

What does it mean to be a DMEA Cat 1A Trusted manufacturer?

A semiconductor fab that is DMEA Cat 1A Trusted is one that has been approved by the Defense Microelectronics Activity, or DMEA, to handle sensitive military and government contracts. This certification is only given to facilities that meet the strict security requirements set forth by the DMEA.

Being DMEA Cat 1A Trusted means that SkyWater has implemented extensive security measures to protect against the potential theft, sabotage, or exploitation of sensitive information or technologies. These security measures may include physical security, background checks for employees, secure data storage and transmission and strict access control policies.

How does SkyWater help move technology from the lab to the fab?

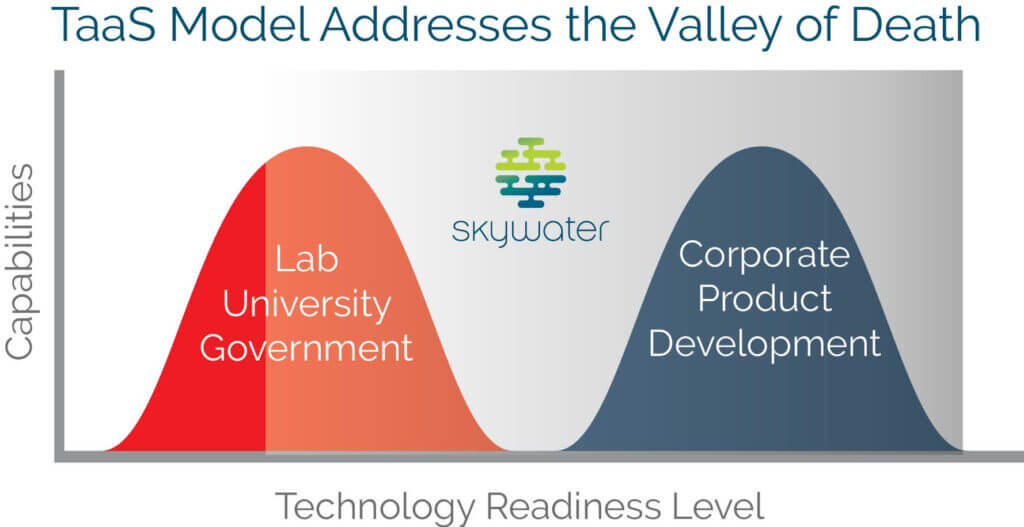

SkyWater’s Technology as a Service business model addresses the Valley of Death by engaging our manufacturing capabilities early in the development process. With TaaS you’re beginning the foundry engagement at earlier technology readiness levels than the norm in the industry. This model supports co-creating differentiated solutions in an agile environment where engineering teams work with design teams to create an optimal end-state solution – a product that delivers differentiated value and is also highly manufacturable.

Read more about TaaS.

What is SkyWater’s 90nm Strategic Rad-Hard by Process Early Access Program and how do I get started?

SkyWater is collaborating with a select group of organizations through an Early Access Partner Program focused on the 90 nm Strategic Rad-Hard by Process technology.

By participating in this program, partners can take advantage of several benefits, including access to exclusive pre-market communications and program updates. Additionally, partners can represent their technology needs and contribute to the definition of design and platform IP requirements, as well as participate in design engagement planning.

The Early Access Partner Program offers a unique opportunity for partners to engage closely with SkyWater and provide valuable feedback on the development of this cutting-edge technology. The program allows partners to have an active role in shaping the future of strategic rad-hard technology and ensuring that it meets their specific needs and requirements.

If you are interested in the Early Access Partner Program, request your spot today or stop by booth 404 at GOMACTech to chat with us.

What technologies does SkyWater offer to enhance rad-hard performance for aerospace and defense applications?

SkyWater is implementing VORAGO’s HARDSIL® technology into radiation-hardened and radiation-tolerant devices for commercial, aerospace, and defense applications. The partnership allows SkyWater to achieve high-reliability rad-hard electronic components without requiring costly design changes or modifications, ensuring the components can withstand exposure to ionizing radiation and extreme temperatures without malfunctions or failures. This innovative technology streamlines the manufacturing process, reducing time and costs associated with adjustments or modifications.

How does SkyWater’s program targeted for QML Class V help customers?

QML Class V are microelectronic components designed and tested to withstand harsh radiation of space. They meet strict requirements of the Defense Logistics Agency’s Qualified Manufacturer List and are used in mission-critical applications — such as such as strategic systems, satellites and deep space probes — where high performance and reliability are vital.

SkyWater’s RH90 technology is designed from the ground up to meet this rugged quality and reliability requirement. And we do it all in a commercial manufacturing facility, which means we can support your program from development through volume production.

Bring your questions and ideas to GOMACTech 2023. We’ll be in booth 404.

Start the path to commercialization by talking with our experts. We’d love to learn about your priorities and send you off with fun swag from our booth. If you are not able to attend GOMACTech this year, contact us to get started.