By Carmen Cecman, quality assurance engineering manager

Quality is essential in the precise work that SkyWater does — in the accuracy of our products and services — as well as its execution through certified processes. By focusing on quality, our suppliers, employees, auditors and stakeholders make it possible to achieve our mission:

We co-create technology solutions that bring our customers’ ideas to life through an ecosystem of agile development, trusted IP security and quality manufacturing services.

SkyWater is the only U.S.-investor owned pure-play semiconductor and technology foundry with the certifications needed for the most demanding industries and applications such as aerospace and defense, medical, and automotive — where, in addition to longevity, chips require extremely high levels of precision and accuracy. These products must perform reliably for years without maintenance in extreme environments.

Quality is not free

The highest quality levels specify certified processes, including the highest quality materials, running at a volume capacity to support metrology at all check points and quality assurance engineers who are embedded in our Advanced Technology team. While this adds to manufacturing costs — our focus on quality detects defects early — resulting in best-in-class yields and cycle times.

Quality isn’t optional

All SkyWater facilities are ISO 9001 certified, in addition to industry specific certifications. ISO 9000 is a set of quality standards developed by the International Organization for Standardization — so all companies whose quality management systems are ISO-certified have met identical, globally recognized quality requirements. SkyWater’s 9001 designation refers to quality management and quality assurance standards for the design, development, production, installation and service of our product. It is the most comprehensive of all the standards. ISO 9001 certifies the overall organizational structure, procedures and processes at our Minnesota and Florida fabs.

Built on certified processes, our rich development platforms allow innovators to create unique designs into SkyWater Product Development Kits

PDKs enable the integration of a variety of technologies such as: CMOS, radiation-hardened, MEMS, photonics, power management, superconducting, carbon-nanotube SOC — in addition to custom technologies. SkyWater is a tech playground with all kinds of building blocks for innovators — inside an organization with certifications in highly regulated industries.

SkyWater’s Bloomington, Minnesota Fab

Recently expanded in 2020 to enable additional capacity and Cu back end of line, our Minnesota headquarters grows from a rich heritage of technology development and quality volume manufacturing on 200 mm equipment for 90 nm + feature geometries. With 91,000 sq ft cleanroom (class 10), our capacity is 10,000 30 ML CMOS wafers/month or 50,000 MOSFET wafers/month.

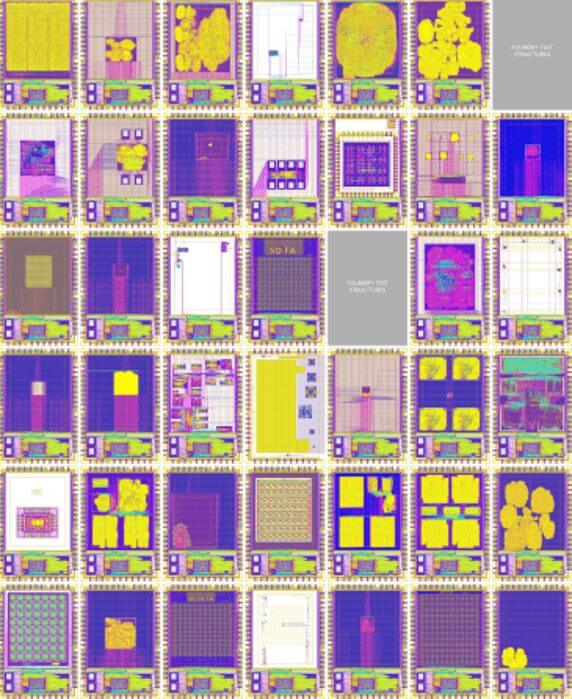

SkyWater’s Minnesota fab can supply customers with an endless number of designs. In the last Google-sponsored shuttle, there were hundreds of tape-outs or different integrated circuit designs as shown in the example above.

Minnesota Facility Certifications

- ISO 9001 Quality Management System

- AS9100 Aerospace Certified

- ISO13485 Medical Certified

- ISO9001 / IATF16949 Automotive Certified

- ISO14001 Environmental Certified

- DMEA Category 1A Trusted

Minnesota facility industry processes are integrated for maximum quality:

- Automotive level: APQP development process, PPAP process requirements, process capability maturity cpk 1.67, extra defects inspections strategy, tighter controls and limits, QA manual reviews and acceptance criteria

- Medical: operational risk management, extra defects inspections strategy, tighter controls and limits, QA manual reviews and acceptance criteria, process validations

- Aerospace: ITAR conforming processes, counterfeit prevention program

- Government: DOD ITAR conforming processes, MIL-PRF-38535 QML Q and V certified facility, Trusted Security Facility Foundry

SkyWater Florida Fab

Through a partnership with Osceola Country, Florida, SkyWater is the sole operator of the state-of-the-art Center for Neovation. Here, we are onshoring the next generation of advanced packaging and custom heterogeneous integration solutions on 200 mm equipment, in 36,000 sq. ft cleanroom (class 1,000 & class 10,000). We engage with customer ideas as early as MRL 3 and accelerates bespoke or highly differentiated process integrations to production to address high quality requirements.

Florida Facility Certifications

SkyWater’s Technology as a Service model enables the highest quality processes for a wide range of customers while operating at a broad mix of products, by employing the following systems and controls:

- Robust Quality Management System that covers the variation of automotive, medical and aerospace requirements: Document Management System, Change Management System, process changes controls, non-conforming product controls, internal audit program, CAPA system, suppliers quality, continual improvements program, risk management, SkyWater Training University

- Production controls to prevent scraps and yield loss: MES tracking system, production automation system, FabTime Performance, Statistical Process Controls

- Equipment maintenance predictive and preventive program: Maintenance Tasks Management, Computerized Maintenance Management Systems, calibrations controls

- Process and equipment engineering systems and advanced controls: Fault Detection Controls, Advanced Process Control

- Stable and capable processes that allow quick cycles of learning through production line enable customers to quickly innovate.

- Monitoring and measurement equipment controls: NIST traceable calibrations, GR&R controls

- Facility advanced controls for environment, particles, ionization, chemicals and gases

- In-house Failure Analysis for quick cycle of learnings, root causes analysis and device yield analysis

To drive quality in SkyWater’s TaaS operating model these are the processes we follow:

- Process Maturity Readiness Levels – will take a customer idea to development stages of a process with the final target to Transfer to Production readiness.

- MSO using Inficon system with dynamic sampling, automatically adjusted sampling rates for an overall reduction in defects, manual log throughs, reduced engineering time over conventional SPC processes.

- List of quality: Design and development of processes using Process Characterizations Reviews and Equipment Procurement Reviews – maturity levels that allows development in stages considering risks, statistical justifications, performance, acceptance criteria.

- SkyWater’s TaaS model ensures customer engagement and collaboration throughout the scoping, development, transfer to production, and wafer services processes. SkyWater’s success depends on understanding our customer’s expectations, so that we can plan and execute to consistently meet them. These customer interactions are “built-in” to our various processes, from initial engagement to the delivery of production wafers.

Quality is not only how we perform internally, but also a matter of the quality that our suppliers bring.

Dedicated suppliers—including companies, manufacturers, vendors, contractors and their employees who sell and provide materials, products, and services to SkyWater—are essential to manufacturing domestic semiconductors. This year, we are recognizing Supplier of Excellence Award winners who exceeded a stringent set of quality performance criteria, played a significant role in supporting SkyWater initiatives and/or contributed to SkyWater’s success by mitigating supply risks. Three award winners are: Toll, Preferred Electric and Central McGowan, in addition to individuals from these companies.

Strong partnerships help ensure our facility runs at peak performance 24 hours a day, seven days a week, 365 days a year. We are very pleased to award, for the first time, top-performance suppliers and contractors who provided outstanding support during critical situations for SkyWater. These suppliers, through close collaboration, also consistently improved their quality systems to provide high-quality products, processes and services to SkyWater. We are looking forward to continually recognizing outstanding partners from our long list approved suppliers, vendors and contractors.

View the Supplier of Excellence Awards page