By Thomas Sonderman, president and CEO, SkyWater Technology

Last week we discussed how the semiconductor industry is changing to meet the needs of our changing world. Today we’re going to talk more about Technology as a ServiceSM and how this business model facilitates innovation in product design and manufacturing.

Technology as a Service

Conventional foundries offer wafer services. Through their own R&D efforts, these foundries create a process design kit, or PDK, that they offer to the market. Development companies then take that PDK and design their products, optimizing the design for a specific platform. Typically, there is very little back and forth between process technologists and the product design team.

Over the past year, I have spoken many times about how the semiconductor manufacturing industry needs to embrace Technology as a Service to facilitate manufacturing for the next wave of computing. The thinking behind the TaaSSM model is much like the thinking behind the Software as a Service model that was used to optimize the way software is brought to market.

Innovation as a Service

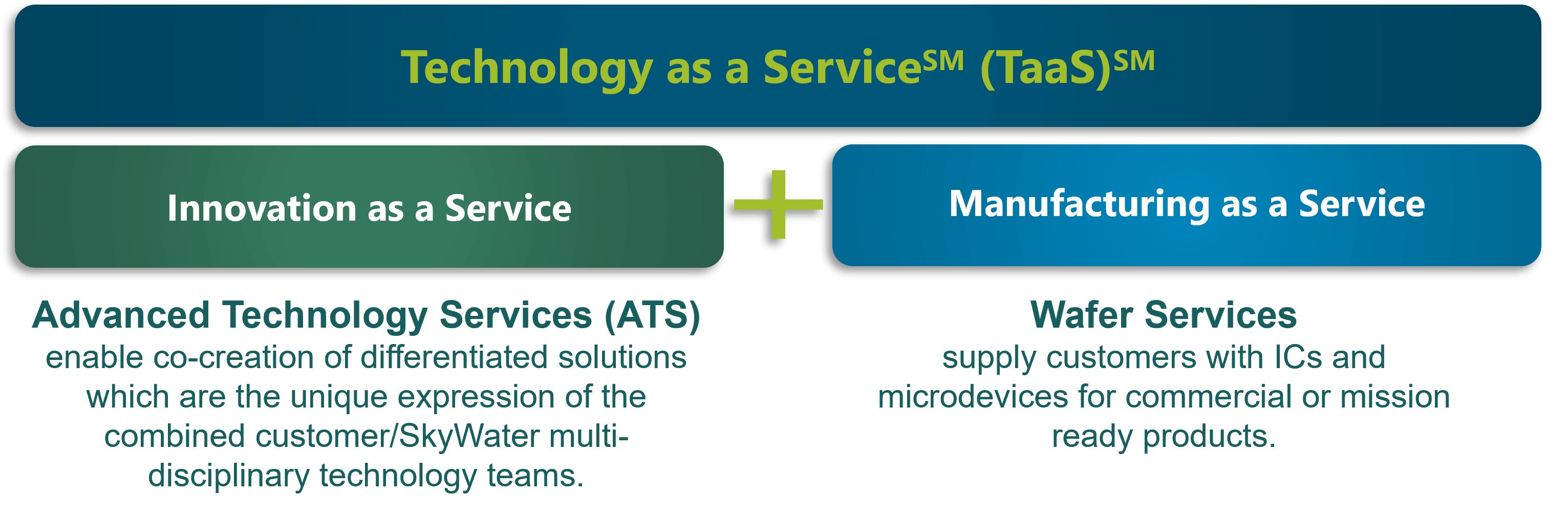

At SkyWater, we deliver TaaS through two key areas: innovation and manufacturing. Let’s focus first on innovation. To support innovative thinking and new solutions, closer collaboration between product designers and process engineers is critical. Through our Advanced Technology Services, we provide sophisticated process technology support for product designers wherever they are in the technology readiness level of their product. This ranges from adjustments of an existing process to improve quality and prepare for volume production to full-on integrated multidisciplinary process/device teams who are working from an early-stage concept.

Manufacturing as a Service

The second part of the model is wafer production. Using a TaaS model, chip designers can engage with the foundry much earlier in the technology lifecycle. Technology development work is done in a production environment. This means that together — chip designers, developers and process engineers — can create novel chips that offer differentiated value. Add the fact that these chips are also highly manufacturable, and you now have a model that delivers the highest possible yields, predictable cycle times, and very robust quality and reliability — significantly accelerating time to market.

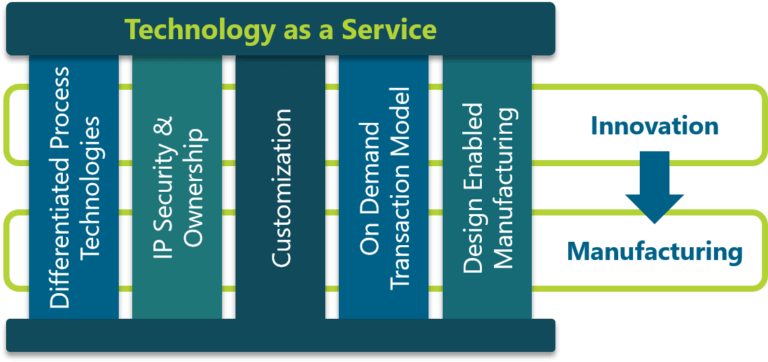

The ability to design and manufacture innovative technologies and support out-of-the-box thinking without the constraints of a fully automated foundry are the driving forces behind TaaS. But how does this all come together? Let’s look at five core capabilities: differentiated process technologies, IP security and ownership, customization, an on-demand transaction model and design enabled manufacturing.

Differentiated Process Technologies

To support the next wave of computing, our industry will see significant development in process technologies such as carbon nanotube, superconducting, photonics and MEMS. These process technologies are precisely the types of technologies that are well served by a TaaS business model. They are driving emerging markets, have varying degrees of manufacturing readiness, and require a mix of process development and product design to be fully realized.

IP Security and Ownership

IP security and IP ownership are both of critical importance in TaaS. From a security perspective, chip designers require assurance that their IP will be protected and that their designs won’t leak to the market. As it relates to IP ownership, in a TaaS relationship, IP is generated in both device and process categories. Both parties come into the business relationship keeping ownership of their own IP, and services are delivered without fully transferring ownership of the underlying assets.

Customization

In a fully automated foundry, only large and well-funded companies can afford customization. TaaS supports the unique needs of each customer and offers customization as needed to enable chip designs. Beginning engagement earlier in the lifecycle for these technologies provides a level of customization not currently available to chip designers in most foundries. The ability to offer agile, customizable processing before a product is fully defined is critical to supporting development. This allows chip designers to bring their ideas to the market without limitation.

On-Demand Transaction Model

An on-demand transaction model facilitates the alignment of customer needs and technology development in real time, improving the efficiency of the overall investment. In a TaaS model, a resource or function can be activated and/or scaled whenever a business situation requires, ensuring that developed technologies are a match for business requirements.

Design Enabled Manufacturing

In contrast to conventional design for manufacturing concepts, Innovation as a ServiceSM places strong emphasis on collaboration between device and process technology teams. This focuses the collective team to leverage robust manufacturing concepts to enhance performance rather than being passive constraints. We refer to this as Design Enabled Manufacturing. When innovating in this DEM environment, the move to production is seamless, enabling rapid scale up, accelerated time to market and reliable manufacturing outcomes – not to mention high yields, predictable cycle times, robust quality and reliability.

About SkyWater

SkyWater is the only U.S.-owned and U.S.-based pure play semiconductor foundry and is a DOD-accredited Trusted supplier, specializing in custom technology development services, volume manufacturing and advanced packaging services. Through its Technology Foundry model, SkyWater’s world-class operations in Bloomington, Minnesota and Kissimmee, Florida provide unique processing capabilities to enable quality production and advanced packaging for mixed-signal CMOS, power, rad-hard and ROIC solutions. SkyWater’s Advanced Technology Services empower development of superconducting and 3D ICs, along with carbon nanotube, photonic and MEMS devices. The company serves customers in growing markets such as aerospace & defense, automotive, biomedical, cloud & computing, consumer, industrial and IoT. Please visit www.skywatertechnology.com/ for more information.

For more information about SkyWater’s TaaS offerings, contact us and a member of our team will be in touch.

You can also watch our What is a Technology Foundry video here: https://www.skywatertechnology.com/about/