By Lead Maintenance Technician Rodney Siem

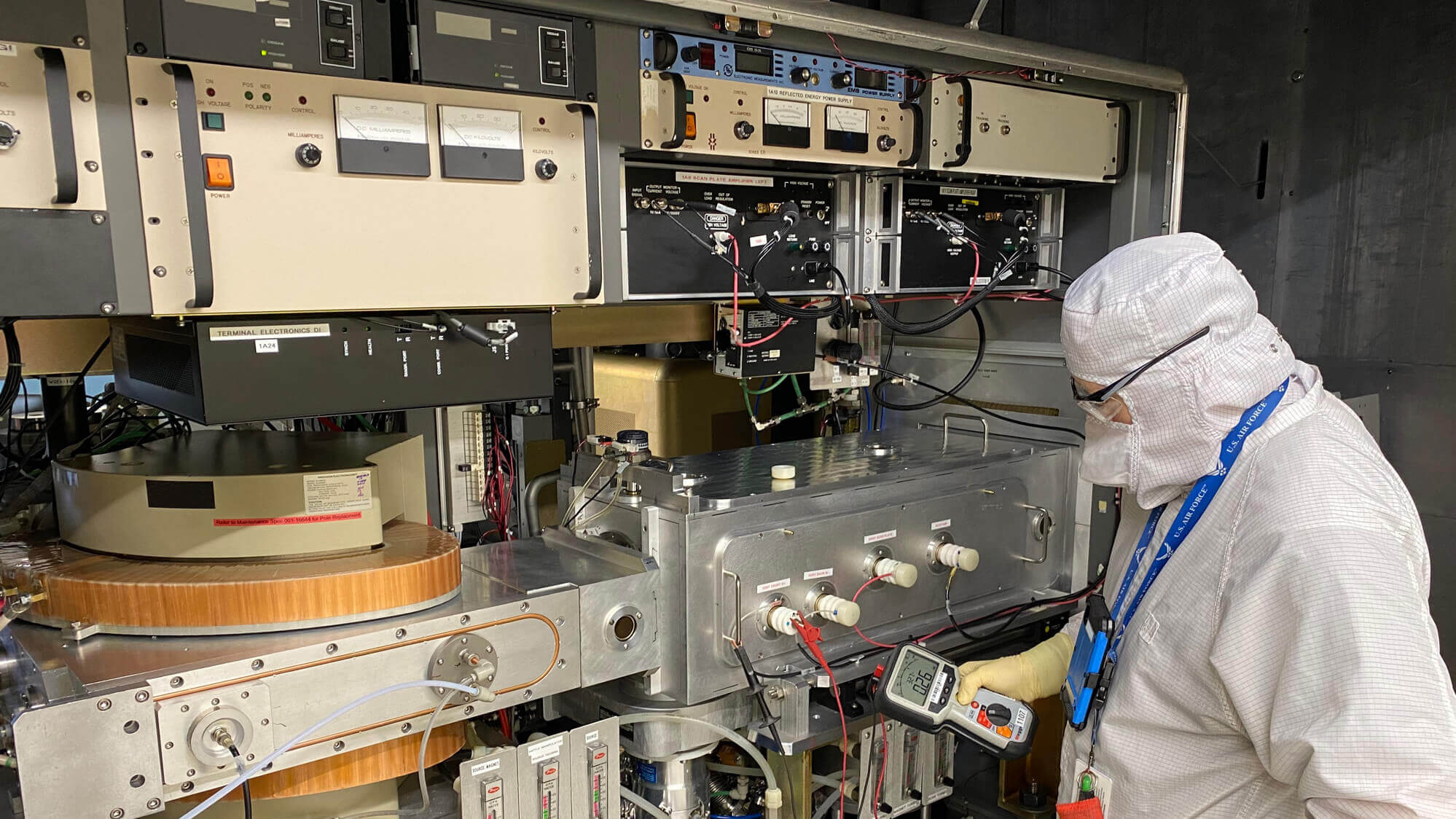

Continuing our “Day in the Life” series, we investigate a day in the life of a SkyWater maintenance technician. Interested to learn more about the career and the types of interesting equipment SkyWater maintenance technicians work on in a semiconductor fab, we sat down with Lead Maintenance Technician Rodney Siem to learn more…

It started with a life-changing interview

After serving in the Marine Corps working on radar systems, I returned to my family in Minnesota and began looking for work. I found that my skillset and mindset were a great match for SkyWater. (Not to mention the fact that I was in search of great medical benefits!)

After serving in the Marine Corps working on radar systems, I returned to my family in Minnesota and began looking for work. I found that my skillset and mindset were a great match for SkyWater. (Not to mention the fact that I was in search of great medical benefits!)

When I interviewed with SkyWater hiring managers — and I saw how technically savvy they were — it made me want to work here. I liked their bold thinking and broad knowledge. Walking through the fab intrigued me because of the vast technologies wrapped into each tool set that I could learn. It looked challenging — like cooking with so many different spices — in each tool. If it were only salt, it would be boring!

I’ve been with SkyWater nearly 24 years now — so I’ve worked with a lot of different equipment and seen a lot of positive changes in our profession. The best part? SkyWater offers the opportunity to work on maintenance projects that you won’t find anywhere else.

What is it like to be a maintenance technician at SkyWater?

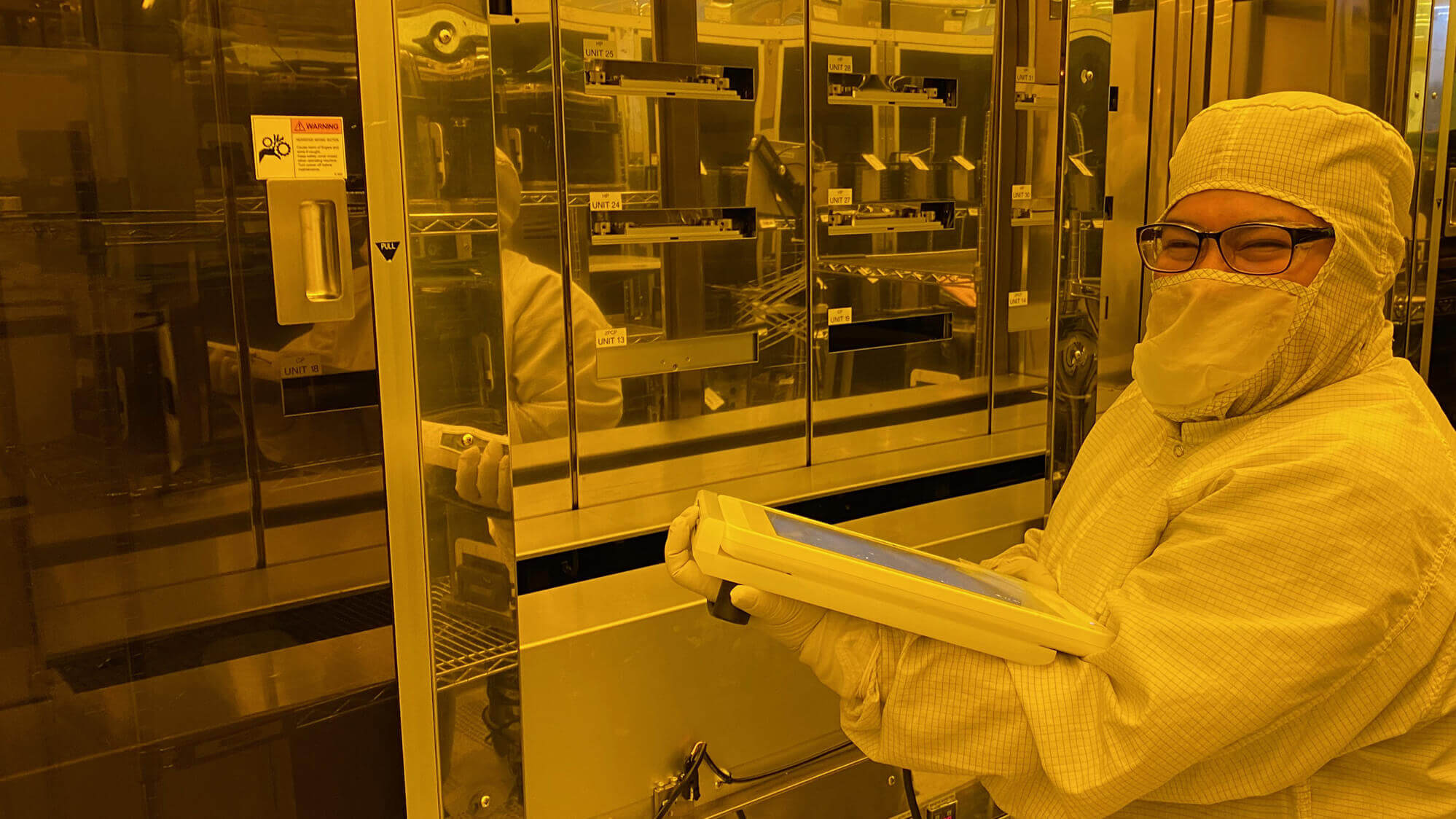

Walking into the fab, Siem reviews his day.

I start my day early because I like quietness in the morning. The flexibility to come in early to get ahead of things is a great benefit. I’m geared that way. If I’m falling behind, I have the flexibility to stay late so that I can catch up on my checklist — or help others.

- When the shifts change, there is a pass-down and we review the day’s events, problems that occurred, and plans to resolve existing problems. It’s a great opportunity for newer techs to learn from more experienced techs.

- After pass-down, I head into the fab to talk with the lead operator. We collaborate with operations to ensure we don’t interrupt critical production.

- I review work orders and prioritize them based on their urgency and importance by referring to a ‘downed list’ in SkyWater’s computerized maintenance management system.

- SkyWater maintenance technicians perform the following work on a typical day:

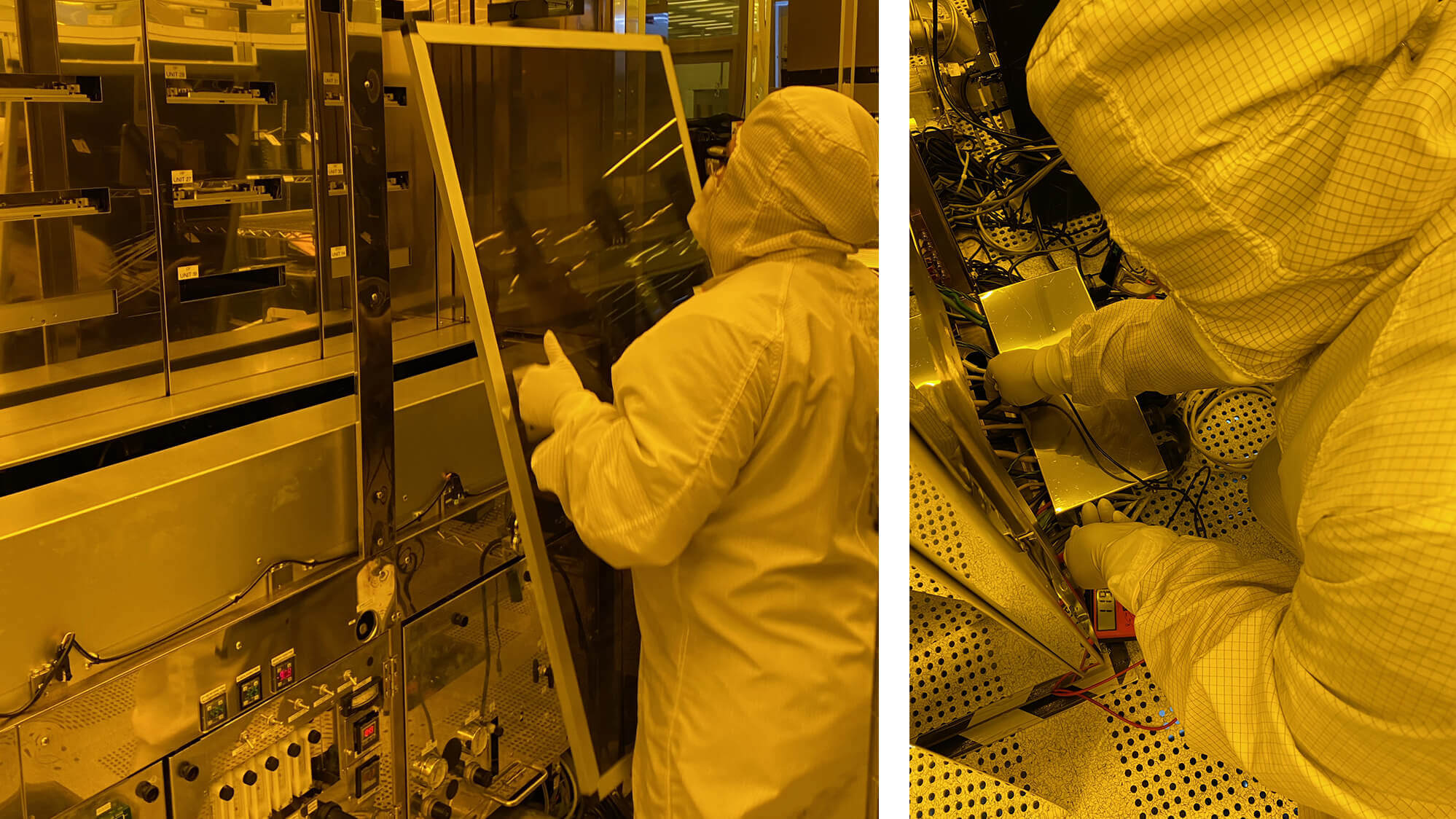

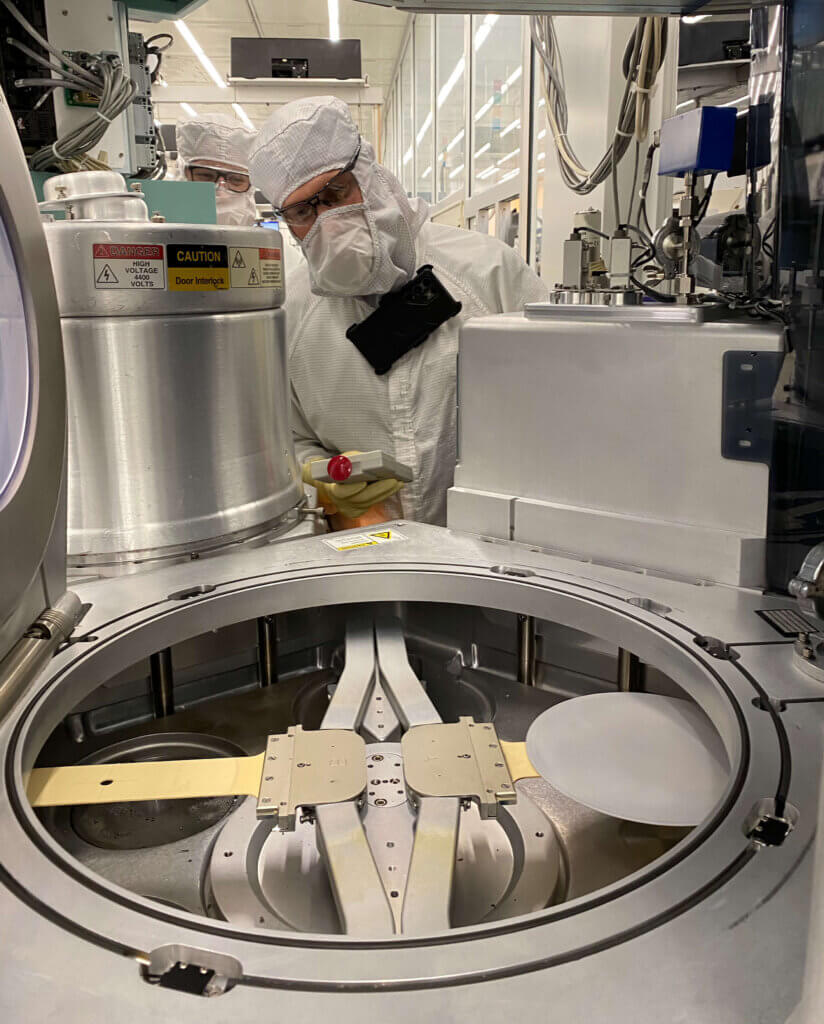

– Dismantle, adjust, repair and assemble equipment according to schematics, specs, OEM manuals.

– Use test and diagnostic equipment to identify problems.

– Perform preventive and corrective maintenance on equipment.

– Complete and maintain required documentation.

– Rebuild equipment and sub-assemblies as required.

– Perform equipment modifications as directed by engineers.

– Participate in maintenance or cross-functional teams.

– Work with outside vendors as required.

– Process chemical and gas handling.

– Maintain critical spares and consumables inventory.

– Attend in-house training to add to your skillset through SkyWater Skills.

– Participate in peer training on new tools and skills.

Your voice matters

My team has a voice. We have the freedom and liberty to make our processes and procedures better. Beyond processes, we can contribute to administrative ideas as well. For example, I’ve suggested cost-saving ideas that have been implemented. When you join SkyWater, you can make a difference and you can have control over almost all aspects of your job.

5. Continuous Learning

While experience working on automobiles, airplanes, or other equipment helps, there is no other place to learn these industry specific tools than on the job. Even for college graduates who studied the industry and have some experience with industry tools — it’s not apples-to-apples. There’s always something new to learn.

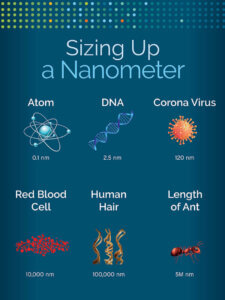

I like that my colleagues are here to support my learning. I can reach out to our engineering staff and learn and grow in that manner, too. It’s not just turning a wrench and greasing a bearing. There are a lot of intricacies to understand. It’s about managing particles — the things you can’t see. You can’t put your hand on it and say, “Yep. That’s a particle!” It requires deeper investigation into the root cause of issues.

6. Interaction with other teams is a common part of the day. Techs work closely with the operations team to understand any issues faced, coordinate with the engineering team for complex technical issues, and provide training to new techs on equipment operation and safety procedures.

That’s the beauty of it. We interact with operators, engineers, management, vendors and suppliers. We engage in all of these different worlds. It’s fun.

7. The day ends with detailed record-keeping and reporting.

Techs document maintenance and repairs, parts replaced, and any observations made during their work in SkyWater’s computerized system. This documentation tracks the health and history of the equipment.

Maintenance technicians can develop their careers in a variety of areas, including engineering

I enjoy my job as a maintenance technician, but I also really like that fact that there are options for maintenance techs here at SkyWater. One Implant tech who worked with metals decided he wanted to try something new, so he transferred to the facilities team and is learning a new side of the business. Another tech I worked with decided to expand his skills and moved into equipment engineering. Another decided she wanted to move into management. Then there are other techs who love their job and want to continue what they are doing — and they become our principal maintenance techs. There are lots of opportunities to grow at SkyWater.

Find a place on our team

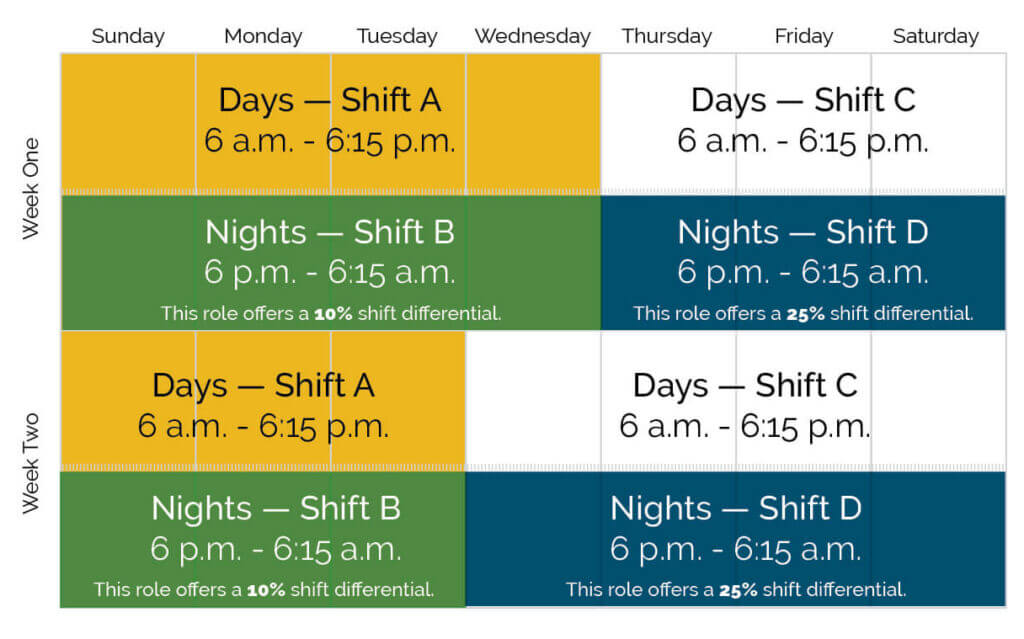

Our fab operates 24/7/365 days per year. Check out maintenance technician openings and apply for a shift.

Days/Shift A Openings in Minnesota

Sunday through Tuesday and every other Wednesday 6 a.m. – 6:15 p.m.

Days/Shift C Openings in Minnesota

Thursday through Saturday and every other Wednesday 6 a.m. to 6:15 p.m.

Nights/Shift B in Minnesota

Sunday through Tuesday and every other Wednesday 6 p.m. – 6:15 a.m.

There are currently no openings on Shift B.

Nights/Shift D in Minnesota

Thursday through Saturday and every other Wednesday from 6 p.m. to 6:15 a.m.

There are currently no openings on Shift D.

How much does a maintenance technician make?

Salary for a maintenance technician varies depending on experience, but is usually within the $28-$40/hour range. New maintenance technicians will receive up to a $7,500 sign-on bonus, depending on experience. The pay-out schedule for the bonus is half in your first paycheck and half after 6 months of employment.

What if I don’t live in Minnesota or Florida?

This is an on-site job, so being in Minnesota or Florida is required. Relocation assistance is available for maintenance technician roles.

Why Stay at SkyWater for 24+ Years?

We asked Rodney Siem why he continues to stay at SkyWater to grow his career. His smile grew as he explained:

There are so many reasons to stay, I like the long weekends, paid time off, 401K match and benefits. I like the daily challenge of learning, and I like the team around me. I also like knowing that what I do makes a difference!

I like having a say, and advancing the cause with our ideas. People listen and give us permission and authority to make changes — so our team gets better. All of the things that we implement as a team have come to fruition though advancing learning. We need to do this to be competitive.

I stay at SkyWater because I like making things better. As a SkyWater maintenance technician, that’s what we do. We make things better!

“Day in the Life” is a recurring blog series published by SkyWater Technology. Join us next time when we dive into process engineering technician roles.

If you want to read our previous “Day in the Life” post about fab technicians, you can find that article here.