By Sr. Development Engineering Technician and Shift Leader Makena Burke

SkyWater development engineering technicians perform experiments for our Advanced Technology Services engineering team in search of the perfect recipe to improve processes and scale production for our customers. Performing side quest experiments is not only fun — it also speeds fabrication and increases quality. In this role, there are options for compressed 12-hour shifts and a standard 8-hour shift — to allow time for personal quests too.

We sat down with Makena Burke who joined SkyWater nearly two years ago as a process technician. She is one of two 12-hour, split-shift leaders, who enjoys mentoring new technicians and our Earn While You Learn techs.

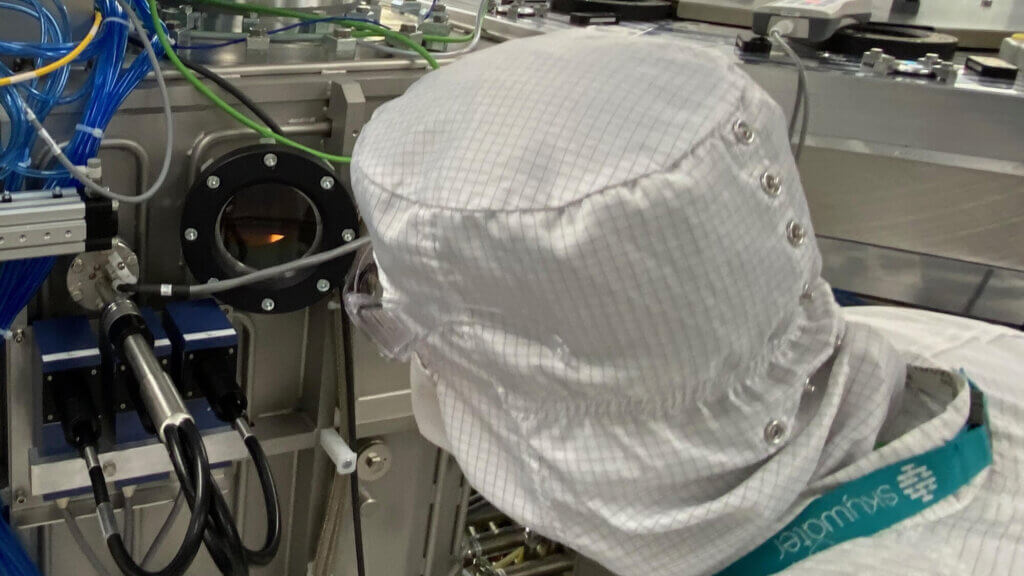

Let’s go behind the glass to see what it’s like to work in a place where you never stop learning and experimenting…

SkyWater has the compressed workday down to a science

I graduated from the University of Minnesota – Twin Cities with a chemical engineering degree called Bioproducts, Biosystems Engineering or BBE — which is a very specialized chemical engineering discipline. We studied the food and biofuels engineering industries, so I learned a lot about designing experiments, and how manufacturing & processing works — which has many similarities to what I’m doing in the semiconductor industry for SkyWater.

I was able to work full-time as a process technician — while finishing my degree at the same time. This streamlined approach was possible because my manager was super accommodating around my class schedule. In Fall 2022 while training, I worked a modified afternoon shift (noon – midnight, Wednesday – Sunday) for the first six months. Then I switched to night shift (6 p.m. – 6 a.m.) in during the Winter semester. I had a great connection with my manager, my team and my trainer regarding flexibility. The compressed work hours really helped.

A recipe for scaling up production

My manufacturing and chemistry background helps me with SkyWater recipes — as we look for improvements for scaling production. I love that at SkyWater, there’s always somebody smarter than you, somebody who knows something different than you — and they’re willing to teach you.

My typical day involves making sure customer lots are moving and looking for ways to improve

1. After pass down, I check my Teams messages to see if anybody needs help. As a lead position, I respond to new technicians and I also make sure our Earn While You Learn students feel confident to do their assigned task — or help them. Our Earn While You Learn techs work part-time for SkyWater while attending school. They can transfer to a full-time position after graduation, which is really nice.

2. I expedite my assigned customers’ work in progress. We work with engineers during the day to get the Problem Lot List, or PLLs, figured out — so that we can keep moving overnight.

3. I track customer lots to keep the tools running and lots moving. We use an app that was created by one of our employees that helps me connect with the right people to get problem lots solved. If it’s an ATS lot and tool problem, I’ll talk with the process or tool engineer, our maintenance tech — and I’ll also work with the ATS manager who owns the lot. This way, we communicate a plan to get the lot moving, and the tool up and running.

4. We speed innovation for our customers by getting ATS requests done within 24 hours. ATS requests and Run Status Changes are engineering experiments managed in the ATS Request Tracker app where engineers have requested side quests to investigate ways we can improve over our standard process — such as a recipe creation on different tools. I look for areas of interest (like a new tool), so that I can self-direct my career. To date we’ve completed more than 3600 requests. In the SkyTech Center, some tools’ quals are not automated — so tool owners put in requests to tell us what quals the tools need to be able to run lots.

- If there is a request that’s a hot lot and really needs to move, the ATS Request Tracker keeps technicians in communication about their projects. It’s also a good way to let new employees guide their own training and advocate for their interests. In the photo above, Makena Burke shows new Technician Lane Frye how to track and expedite customer lots.

5. Some customers require direct, dedicated support every day — so we dedicate technicians to these specific customers. That’s the service level we provide. That’s how we move quickly to production. These dedicated technicians attend meetings for their assigned customer so that they have first-hand experience and contact with the lot. They understand the process deeply and push the customer’s WIP.

6. We log foundry time for our customers. As an ATS technician, I log 11.25 hours of foundry time in my 12-hour shift. I am doing something every minute of my day and billing hours — whether that’s to an administration task, training, or time working for my customers on their lots.

7. You can learn up to 300 tool sets. Many technicians may aspire to work as engineers, so they will eventually transfer to become a process or tool engineer. I think people really value their time as a development engineering technician because they get to learn all different sides of the fab. We can use almost every tool — so it’s a great way to get to know SkyWater.

8. Generally, 70% of my day is in the fab — and 30% is in an office setting performing admin work, training, or taking breaks.

9. Near the end of my shift, I organize my day so I can have a successful pass down for the next person. I try not to start tasks at the end of the day that I know would be stressful for somebody else to complete. We’ll do training checklists and tests, watch videos, get experience with the tools — and then hopefully the next day we’ll search for those requests and return to the tools to really solidify our learning.

What keeps me excited about working here?

Truly my group of technicians. I think that all of us have a really good relationship. We’re a relaxed group, but high-paced. At SkyWater everybody is open to training each other. When I stepped into SkyWater on my first day, I knew that there were so many people I could learn from. I think SkyWater has a lot of employees who want to share what they know. And if you’re able to connect with those people, it makes time here a lot of fun. If you’re working as an ATS technician, SkyWater allows for a lot of time to be part of different interest groups.

I’m part of the SKYward Women’s Group, the Employee Activities Committee and I’m on the Emergency Response Team — where I participated in 40 hours of ERT training. I also like that I can switch around my hours for learning new things. I can even come in for overtime if we have interest group meetings that I’d like to attend when I’m not working. I’m also a part of a morale team where we have held a potlucks and other fun things to help keep employees happy.

I have family and friends in town, so on my time off I attend events in Minneapolis and St. Paul like art and live music, go to different museums, and explore with my roommate. I also played in the U.S. Pond Hockey Championships this winter on Lake Nokomis.

There are many shifts and career paths available

Wafer services technicians who have acquired valuable experience can grow their careers with SkyWater in the ATS group — in a specialized photo or etch area. Others move into engineering. We value our employees’ experience and skills to help solve problem lots during their respective shifts and aggressively promote from within.

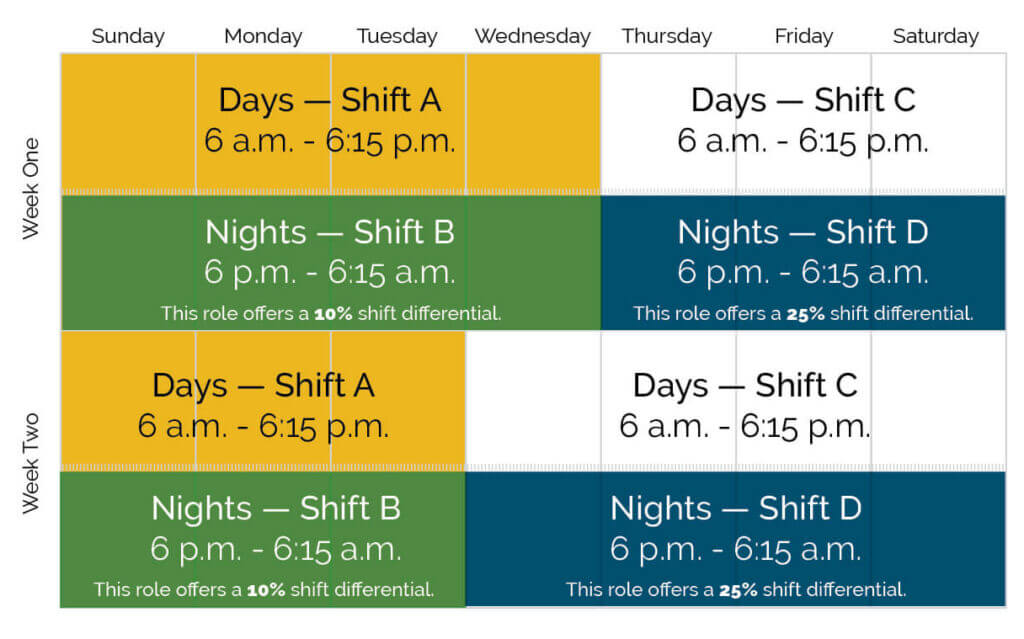

A variety of shifts are shown below.

Curious and want to learn more? Explore what’s possible.

View Current Development Engineering Technician Openings

View All Openings

Find your place at skywatertechnology.com/careers